11. WINDOW HOODS

Surprisingly, window hoods came into general usage only at the end of the nineteenth century as Queenslanders belatedly adapted their houses for the tropical climate. They remained popular until the 1930's, becoming progressively less elaborate with time. The Woodworkers' Company makes metal hoods as pre-assembled units or supplies timber hood designs as either complete kits (incorporating metalwork, screws and flashings) or as timberwork only components. Special hood designs can be quoted, if required.

TIMBER & TIN HOOD PRICE LIST (inc GST)

Woodworkers'

Standard Paling Skillion

Overhang 565 mm

Height 1300 mm

WH 1

Woodworkers'

Diagonal Skillion

Overhang 565 mm

Height 1300 mm

WH 2

Woodworkers'

Lattice Skillion

Overhang 565 mm

Height 1300 mm

WH 3

Woodworkers'

Sweep Skillion

Shown with fretwork fascia

option at additional cost

Overhang 565 mm

Height 1300 mm

WH 4

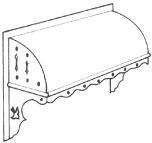

Woodworkers'

Florentine Paling

Shown with fretwork fascia

option at additional cost

Overhang 565 mm

Height 1300 mm

WH 5

Woodworkers'

Fretwork Paling Skillion

Overhang 565 mm

Height 1300 mm

WH 6

Woodworkers'

Bullnose Lattice

Overhang 565 mm

Height 1300 mm

WH7

Woodworkers'

Fretwork Bullnose

Overhang 460 mm

Height 920 mm

WH 8

Woodworkers'

Scallop

Shown with fretwork fascia

and finials at additional cost

Overhang 565 mm

Height 1300 mm

WH 9

Woodworkers'

Sunrise Skillion

Overhang 565 mm

Height 1300 mm

WH 10

TIMBER & IRON HOODS

WHAT IS THE CONSTRUCTION OF TIMBER & IRON HOODS?

All Woodworkers hoods are made of externally durable hardwoods (not pine) and often premium timbers e.g. red cedar, kwila are used to recycle smaller off-cuts from our joinery workshop. Timber hoods are supplied as raw timber in kit form for site assembly by others as they are generally too heavy and bulky for workshop fabrication. Window hood kits are supplied as either timberwork only (excluding all metalwork) or as complete kits including flashings, iron roofing and roof fixing screws. A choice of standard galvanised steel, zincalume or colorbond is available in either standard profile or mini orb, although significant cost surcharges and lead times may apply to mini orb options. All fixings used in window hoods are coated to resist corrosion.

HOW ARE TIMBER HOODS INSTALLED?

Timber hoods are generally constructed on site in the same sequence as you would use to build a roof. Because timber hoods are relatively heavy and bulky it is usually preferable to construct them in position rather than prefabricate them on the ground and have to manipulate them over scaffold into position. The two sides are usually positioned either side of the joinery to enable solid fixing (batten screws) into the stud framing around the joinery. The purlins can then be accurately cut to fit the sides and batten screwed into position to create a sturdy frame for installation of the metalwork. It is preferable if all timberwork is fully primed or finished before installation as it is safer and simpler to do this work at ground level. The size of the purlins needs to comply with the Australian Standard AS1684.2 - 2006 for the wind classification applicable to the locality using F17 unseasoned hardwood (Supplement 15).

The following table is provided as a guide but should be checked by your engineer particularly in heavy exposed or cyclonic areas.

| Size (H x W) | Max Span |

| 75 x 38 | 1600mm |

| 75 x 50 | 1900mm |

| 100 x 38 | 2500mm |

| 100 x 50 | 2900mm |

| 125 x 38 | 3600mm |

| 125 x 50 | 3900mm |

| 150 x 38 | 4300mm |

| 150 x 50 | 4500mm |

The metal work is fixed to the timber structure in accordance with the same code requirements used for the roof, usually requiring nylon washered hex head roof screws. Woodworkers do not arrange installations of hoods but can recommend a BSA registered builder to undertake the work directly contracting with you if required.

CAN WOODWORKERS MAKE SPECIAL DESIGN TIMBER WINDOW HOODS?

Yes. If matching of existing hoods is required we will need photographs and a template to follow, or one side of an existing hood. We do not undertake site measurement of hoods. If you want to design your own hoods, we can work from detailed drawings provided by you.

DO TIMBER HOODS COME WITH DECORATIVE FASCIAS?

No. Even if the design shown overleaf shows a decorative fascia e.g. WH4 & 9, the kit price does not include this feature. A separate price column is included for fascias in the price list and any design can include this if requested at the time of ordering.

DOES WOODWORKERS CARRY STOCKS OF ALL WINDOW HOODS?

No. All metal hoods are custom made and only the WH1 Standard Paling Skillion design is generally held in stock for immediate supply. All other hoods usually require a lead time of 3 to 4 weeks, which can be extended in peak periods.

INSTALLATION INSTRACTIONS

STEP 1

Fix both sides of hood either side of window ensuring solid anchor into wall studs. Fix with 3 battenscrews each side or suitable masonary anchors for brick/block walls. Position the top of the hood to ensure it will not interfere with the opening of the window.

STEP 2

Measure and cut purlins to fit tightly between window hood sides, predrill each purlin end for two batten screws and fix off to create a solid roof frame.

STEP 3

Measure and cut side flashing with angle on top end to fit snugly to wall. Screw fix flashings in place.

STEP 4

Lay out roof sheeting, overlapping stock sheets as necessary to achieve the desired width. Fix roof sheeting every 4th corrogation with roof hex head screws. Position top fixings to ensure they do not interfere with the back flashing installation.

STEP 5

Measure and cut back flashing to sit neatly between side flashing. Scribing of flashing to the corrogation is not usually required. The rear flange is either trimmed to sit in weatherboard overlap, mortar coursing or face fixed into a silicone bed.

METAL HOODS

WHAT IS THE CONSTRUCTION OF METAL HOODS?

Woodworkers metal hoods come in two forms

- galvanised steel

- colorbond zincalume

The primary difference is, of course, the pre-finishing of colorbond hoods but both are equally durable. Galvanised steel hoods are made from 0.4mm (26 gauge) thick steel and are made with traditional solder joints. Colorbond hoods can only be connected by pop rivet joints and are slightly more expensive due to increased material and labour costs. Any current colorbond colour can be chosen for any metalwork feature, including roof vents, hoods, rainwater heads etc. but it is important that water does not run over zincalume onto galvanised product as electrolytic corrosion will occur. You should choose the same material as your roof for gutters, hoods and embellishments to avoid electrolytic problems. Water flow from galvanised to zincalume is acceptable but not the reverse.

ARE SPECIAL DESIGNS TO MATCH EXISTING HOODS POSSIBLE?

Yes. In general we will require either the old hood to be duplicated or a template of the sides and key decoration with photographs to match existing hoods. There is a surcharge of approx 20% for custom work but this may increase with complex designs. Woodworkers do not site measure existing hoods. Special work in other metals e.g. copper can be priced if required.

ARE METAL HOODS SITE DELIVERED?

Usually yes. Metal hoods and roof products are extremely fragile until such time as they are installed in their final position. In metro Brisbane and regional locations near our showrooms delivery is usually not a problem but for country or interstate locations special arrangements are necessary. It has been our experience that metalwork goods are too delicate for normal road transport companies and that fully insured delivery by furniture removalists offers the best chance of success. Special boxing can be arranged at significant expense (if required) but no packaging is provided as standard with metalwork products and it is essential that special top load arrangements are agreed with your proposed carrier. Where you have many hoods the same size, it is preferable that they be adjusted in size in approx 30mm width increments to allow them to be packed inside each other for transport. Our staff can assist with precise increments for your chosen hood design in consultation with our fabrication shop if requested.

DO ROOF VENTILATORS REALLY WORK?

Traditionally roof vents are installed at the apex of the roof to let hot air escape. Roof vents are provided as cylinders which need to be fitted and flashed by a tradesman roof plumber to be effective and weathertight. They are not generally suitable for DIY installations as they require carefully fitted flashings to all adjacent work to both secure them in position and prevent leakage. Where an updraught is essential to extract air, roof vents can be custom manufactured to incorporate a "whirly bird" extraction device or electric fan at additional expense. As with all custom work, lead times of 4 to 6 weeks may be required.

DOES WOODWORKERS ARRANGE INSTALLATION?

No. You will require a specialist roof plumber to undertake installation of ventilators, acroterias, horns, spikes, cappings and rain water heads. Your carpenter will normally install window hoods but, if required, a BSA registered builder can be recommended by our showroom staff to undertake the work required.

HOW ARE METAL HOODS INSTALLED?

Metal hoods should clear the external jambs of joinery by approximately 30mm and are usually simply screwed directly to the chamferboards with dome head screws & nylon washers to ensure electrolytic compatibility with the hood metal. Remember water cannot flow over zincalume onto galvanised fixings. Because metal hoods are so light they can easily be installed by two people in a fully assembled state. The metal hood needs to be positioned to avoid interference with the window opening (especially with casements) and ensure pedestrian traffic cannot collide with the hood. Ensuring the hood and window are parallel, the top flange of the hood is usually slipped under the chamferboard or weatherboard overlap and the sides are screwed down with 3 to 4 screws each side.

Woodworkers' Ogee No.1

Overhang 480mm Height 830mm

MH1

Woodworkers' Ogee No.2

Overhang 480mm Height 810mm

MH2

Woodworkers' Bullnose No.1

Overhang 470mm Height 440mm

MH3

Woodworkers' Bullnose No.2

Overhang 480mm Height 560mm

MH4

Woodworkers' Bullnose No.3

Overhang 480mm Height 560mm

MH5

Woodworkers' Bullnose No.4

Overhang 480mm Height 620mm

MH6

Woodworkers' Skillion No.1

Overhang 450mm Height 380mm

MH7

Woodworkers' Drumroll No.1

Overhang 420mm Height 630mm

MH8

ROOF EMBELLISHMENT

Roof ventilators and classically inspired embellishments were most popular from the early 1880's until World War I. Although originally designed to convection cool and dignify large pyramid roofs, they have become synonymous with the tropical colonial style.

Woodworkers' Drumroll No.2

Overhang 450mm Height 425mm

MH9

Woodworkers' Drumroll No.3

Overhang 450mm Height 380mm

MH10

Woodworkers' Ridge Horn

Height 270mm

Length 300mm

Woodworkers' Roof Ventilator

Small - Height 980mm

min. diameter - 200mm Base diameter 360mm

Large - Height 1200mm

min. diameter - 280mm Base diameter 500mm

Woodworkers' Gutter Acroteria No.1

Height 135mm

Length 360mm

Woodworkers' Square Rainwater Head

Height 330mm

Width 340mm

Woodworkers' Gutter Acroteria No.2

Height 135mm

Length 360mm

Woodworkers' Hexagonal Rainwater Head

Height 370mm

Width 350mm

Woodworkers' Roof Spike No.1 Height 600mm Width 140mm

Woodworkers' Roof Spike No.2 Height 600mm Width 400mm RE8

METALWORK PRICE LIST (INC GST)

CLICK HERE TO VIEW AVAILABLE COLORBOND COLOURS

INSTRUCTIONS FOR INSTALLATION OF PRIVACY SCREENS

Privacy screens manufactured from surian red cedar for durability

Paint prime all timberwork before assembling screen.

Privacy screens are supplied as kits for DIY assembly and installation on site. Screw uprights to inside of window hood framework as per detail A. Where span of louvre blade exceeds 1 meter, one or more central uprights will be required to be screwed to inside of purlin as per detail B.

Screw fix stainless steel brace to foot of screen upright and hood frame with stainless steel screws. Intermediate uprights should also have braces wherever possible.

Screw fix louvre slats from bottom upwards taking care to ensure uprights are vertical and spacings equal. Finally, coat all timberwork on completion.

My Account

My Account My Wishlist

My Wishlist My Enquiries

My Enquiries